EcolEner ®: Sustainable Ecological Energy Saving Technology

ECOLENER ® Photon Saving Technology

Sustainability is emerging as an important approach that manufacturing companies employ to improve their economic profitability and competitive advantage by enhancing environmental performance.

Consistent with the contemporary aspects of ecological responsibility, specific forms of ECOLogical ENERgy saving used in our PhotonWeld Laser Welding Machines (with ECOLENER ® technology), do help positively to improve drastically the relationship between an environmental sustainability orientation and environmental performance.

Eco-Friendly Welding solutions and Practices for 2022 and Beyond

The industrial world needs welding. As the popularity of metal structures and constructions rises, more skilled welders are required. However, welding is an energy-intensive process and not so friendly to the environment. In large factories, a lot of energy used by welding and some polluating fumes are also produced.

As the world moves towards protecting the environment, the welding industry can not leave behind. The welding industry must make a great effort to reduce their ecological footprint! Small and big things can help to do this and there are several eco-friendly practices that welders can engage in to reduce their carbon footprint. To do that, welders need to look at the entire welding process to understand which part of the process affects the environment more. From there, the welder can reduce their carbon footprint by tweaking the:

- Welding speed

- replace high energy consuming older welding systems with the latest "GREEN" welding systems

- The raw materials

- Processing time

- System costs

- Filler metals, and

- Seam quality

- But mostly look for Energy saving technology in welding like laser welding in general. Our supplementary Ecolener Photon saving technology gives you even a bigger advance in saving energy.

There is a need for a reduced carbon footprint in all industries. The welding industry can reduce its footprint by reducing the energy they use by making the process more efficient and eliminating the use of older energy hungry welding systems. Older systems lead Flux, and flux leads to the release of gases and fumes that are harmful to the environment.

To save the environment, welders around the world need to educate on the above eco-friendly techniques and to replace their energy hungry systems by modern energy saving welding systems like our PhotonWeld. Individuals as well as companies, have a role to play in saving energy, making the air cleaner and the environment safer for the generations to come.

What is lasermach doing for a more environmentally friendly welding?

The first step towards greener welding is to improve the energy efficiency of thelaseer welding machines.

Improve the energy efficiency of our PhotonWeld-Series is an action with a dual value: reduction of emissions and increase in productivity of the welding process.

The biggest energy savings can be obtained by changing the conventional welding to the very high efficient PhotnWeld laser welding, which can reduces the energy consumption till 90%! And our PhotonWeld series consumes at least 22% less than any other laser welder in the market! Thats real savings!!!

Emissions are reduced drastically with our PhotonwWeld series, through the use of new welding solution created by our Photonweld laser welding machines. Much shorter and much faster weldings, drastically treduced heath input, high speed welding of microweldings which are even stronger than the material itself. With laser welding we use only wire out of the same metal as th eone welded as consumable, which is only melted and does not need special treatment or covers. Much less fume with laser Welding;

Reduced HAZ - Reduced Heat-Affected-Zone

Almost invisible Heat Affected zone

Most of a laser’s energy goes into making the weld itself, with very little wasted on heating the surrounding area. Less waste means lower utility bills.

Improving Laser Welding Efficiency

ECO-EFFICIENCY

Time to reflect

EcolEner Technology means decreasing the carbon footprint of our customers by reducing emissions in their operations with the help of our products.

This is a long-term, maybe never-ending, mission.

At Lasermach, we work hard to reduce the emissions caused by our own produced welding machines.

EcoLener 976nm:

The new Green Number

Our EcoLener 976nm pumped high efficient fiber laser Sources achieves 85% optical efficiency with a Wall-Plug efficiency of almost 50%, which is much higher than any other wobble laser Welding Machine.

976nm pumped fiber laser achieves 85% optical efficiency

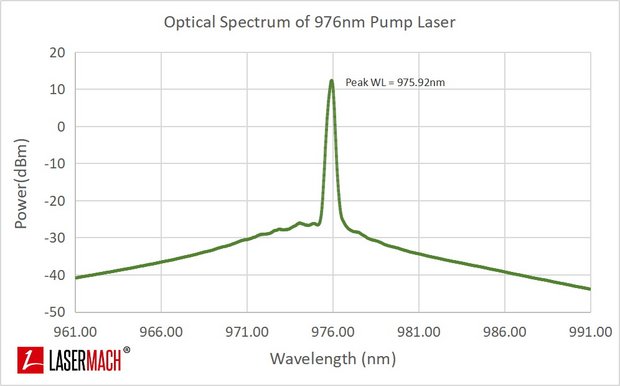

The 976nm pumping solution has obvious advantages and will gradually become the mainstream of the market.

The current laser welder equipment in the market are mainly water-cooled solutions, that is, heat is taken out of the laser through the external circulation of the chiller. Lasermach's PhotonWeld focuses on continuous discussion and innovation based on 976nm technology, combined with the high photoelectric conversion efficiency of 976nm Creatively solved the problem of air-cooled refrigeration capacity, launched the air-cooled 976nm technology for the first time in the industry, solved the power consumption and portability issues, and once again lead the technical development direction of fiber lasers.

The 976nm semiconductor laser is applied to the high-power fiber laser in the industrial market. Due to the elimination of the nonlinear effect of the fiber, nearly 85% of the light-to-light conversion efficiency is achieved, the whole system is weakly affected by the ambient temperature, and the reliability of the semiconductor laser itself is higher. Many advantages will be more and more valued and welcomed. In the long term, with the scale application of the 976nm fiber-coupled module, it is believed that the product technology level will continue to improve, and low-cost 976nm wavelength locking on components will become a reality.

The 976nm EcolEner Technology has a higher electro-optical conversion rate

Why other friends widely use 915nm pump source

Since the absorption of 976nm is 3 times that of 915nm, the 1070nm output laser that produces the same power consumes much less 976nm pump light. The pump light is converted from electrical energy, which means that the use of 976nm pump source consumes less electrical energy, higher photoelectric conversion rate, and more efficient energy saving. Comprehensive analysis shows that the electro-optical conversion rate of 915nm is about 30-32%, while the electro-optical conversion rate of 976nm can reach more than 48%.

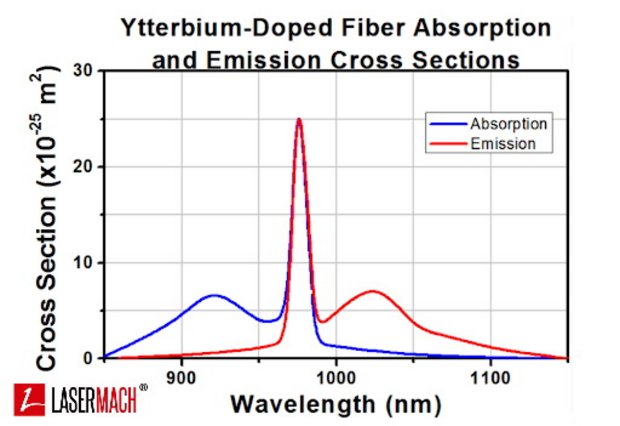

Since ytterbium-doped fibers absorb light better at 976 nm wavelengths and have higher light conversion, why did most lasers, including now, use 915 nm pump sources?

Looking closely at the above figure, we can find that the absorption peak of 976 nm is relatively high but very narrow; while the absorption peak at 915 nm is relatively low and wide, and the height of the absorption peak is only one-third of 976 nm, but the absorption spectrum width is about 5 of 976 nm Times or so. For 976nm, a slight change in wavelength can seriously affect the absorption rate.

The output wavelength of the laser diode will drift with temperature. Typically, the temperature drift coefficient is about 0.31 nm/°C. This is reflected in the fact that temperature changes have a greater impact on the performance of the laser.

The absorption peak of the ytterbium-doped fiber in the 915nm band is wider, and the wavelength drift of the laser diode has little effect on the absorption efficiency, and the laser is more stable and easier to control for the design of fiber lasers. As a result, the 915nm pump solution has been widely used in the fiber laser market in the past.

Fiber lasers are usually industrial processed in a high temperature, high humidity and dusty environment, and gain fibers and key solder joints are prone to aging in this environment for a long time, affecting beam quality and output efficiency. Lasermach independently developed EcolEner 976nm two-way pump optical fiber winding reel structure, the use of sealing rings and covers to seal the internal fiber and welding points in the winding reel, on the one hand to ensure that the heavy heat load at both ends of the fiber can be effectively dissipated, on the other hand for the external environment temperature and humidity has a certain isolation, can reduce the occurrence of condensation, and prevent dust from entering to improve the stability of the laser. At the same time, different loop radius can effectively filter out different specific high-order modes, and the output spot quality will be closer to single mode.

In addition, the optical energy density of the 976 nm wavelength is high, so the return light and residual light are highly likely to damage the internal key components, so their processing is also crucial. EcolEner’s ABR anti-high reflection technology with independent intellectual property rights technically solves the problem of device damage by designing residual and return light stripping devices at key positions inside the laser and ensures the stable operation of high-power lasers.

The 976 nm chip is more reliable than the 915 nm chip and has a longer life expectancy!

The 976nm semiconductor laser pump source as a core device also improves the reliability and life expectancy of the fiber laser machine.

As far as the semiconductor laser itself is concerned, the 976 nm chip is more reliable than the 915 nm chip and has a longer life expectancy. Although the GaAs epitaxial crystal material has a slightly better photoelectric conversion efficiency in the 915 nm, the photon energy is lower due to the longer wavelength of 976 nm, and the cavity surface damage threshold of the high-brightness semiconductor laser chip under high current operating conditions is improved. In other words, the 976nm chip has a lower probability of cavity surface optical catastrophic damage (COD) than the 915nm band chip, and the chip itself is more reliable. Therefore, the 976nm semiconductor laser pump source as a core device also improves the reliability and life expectancy of the fiber laser machine.