Click HERE to visit our new PhotonWeld Website

All latest info on ourPhotonweld Series of laser welding machines here to find

Lasers are Dangerous to Eyes

Experts classify laser emitting devices according to the wavelength and power of the beams they generate, and, consequently on how much danger they pose to users.

Because laser beams are so tightly focused, they are quite dangerous. Even a small amount of laser light can cause permanent eye injury, burning the retina, and therefore government regulations control exposure.

Most of the danger from laser light comes from the heat, but at some wavelengths there are also dangerous photo-chemical effects. With high-powered lasers, even reflected diffuse light can damage eyes. However, most of the danger from laser beams comes from its coherence, concentrating an intense amount of energy upon a tiny spot of the retina, destroying photoreceptor cells.

Infrared lasers, mostly used in our wobble Welding Machines, pose a particular hazard. Because they cannot be seen, they do not trigger the eye’s blink reflex.

Powerful lasers in the 400-1400 nm range penetrate the eyeball and heat the retina. At other wavelengths, the cornea and lens absorb the energy, leading to cataracts or burns. The retina has no pain receptors, so exposed workers often don’t even know they’ve been injured until they detect the resulting vision problems.

Laser Welding Protection products for industry

Working with laser systems and laser welding equipment involves higher health risks.

Therefore, protect your employees with suitable equipment!

Our certified laser safety goggles and windows as well as the large-area shields ensure maximum safety.

You are unsure which product is the right one for your company? We will be happy to advise you personally and develop individual solutions for your needs on request.

Good Eyes Safety Requires Wearing Protective Eyewear When Using Welding or Cleaning Lasers

Protection Glasses and goggles are clasified by its Optical Density (OD).

Glasses and goggles are clasified by its Optical Density (OD). That is the base-0 logarithm of the attenuation factor by how much the filter reduces the beam’s power. For example, glasses with OD 2 reduce the laser beam by a factor of 100 (10²), glasses with OD 3 reduce the laser beam by a factor of 1000 (10³), ...

Required eyewear must reduce the OD to a power below the maximum permissible exposure.

You must also make certain the lenses and frames of the glasses are physically strong enough to take a direct hit from the laser without breaking. Therefore, you must also take into account their damage threshold. The OD and light wavelengths the glasses protect against are usually pad printed on the frames or in the glass.

The wavelength affects calculating the Optical Density (OD). Also, laser operators must wear the glasses specifically for that laser’s wavelength. Laser glasses for another machine, with a beam of a different wavelength, are not safe even if their OD is just as high.

How to Choose Your Laser Safety Goggles? - How to Choose Your Laser Safety Glasses?

OUR 1064 ~1084 nm SELECTED LASER SAFETY EYEWEAR For LASER WELDING - Soon available 2022 - 01

1064 ~ 1084 nm FIBER LASER SAFETY GLASSES - 1064 ~ 1084 nm YAG LASER SAFETY GOGGLES - Laser Welding Safety Eyewear

GREEN Type 1 Eyewear Filter Material for Laser Welding

GREEN - VLT 62+ - OD7+

-

Green Colour protection

- Recommended for all wobble laser welding material

- Very good visibility

- Red pointer fully visible

- Good protection

- Optical Density for Wleding laser Light: OD 7+ CE

- Filter: 190~450nm OD7+ & 800~1100nm OD7+

- Visible Light Transmittance rate: VLT 62-64% : very clear and good view

- Fully coloured material, no scratchable coating

- Resist frontal laser shots

ORANGE Type 2 Eyewear Filter Material for Laser Welding

BRAUN VLT 42-46% - OD8+

-

Braun Colour protection

- Recommended for bright Splattering welding material

- Very good visibility

- Red pointer fully visible

- Good protection

- Optical Density for Wleding laser Light: OD 8+ CE

- Filter: 190~540nm OD3+ & 800~1100nm OD8+

- Visible Light Transmittance rate: VLT 42-46% : very clear and good view

- Fully coloured material, no scratchable coating

Testing laserwelding protection goggles with frontal laser shots

Good Laser welding Protection Goggles

Available Models We Selected for You!

Perfect Eye protection for everybody - Certified Laser Safety Glasses

Model 01 - Multi adjustable Frame Goggles

Excellent fitting Frame goggles for everyone

The Model 01 - Frame Spectacle fits large heads and faces. Fits over most standard prescription glasses. Pros include high comfort and side-protection with a wide view of vision. This is our second most popular frame and is our best option for good fitting with adjustable settings.

This model offers improved fitting functions including angle adjustment for the gap with the face and flexible temples

Light and compact two-lens type is easy to wear and remove.

This model features a highly protective cover frame and wide temples.

Available in OD+7 & OD8+

- green – protection range 190-450 & 800-1100nm O.D 7+ in White or black frame VLT 60%

- Orange – Protection Range 190-540 O.D 3+ 800-1100nm O.D 8 in White Frame VLT 35%

Model 08 - Frame Fit-over

Good fitting Protection Goggles for eveyone with and without prescription glasses!

The Model 08 - Frame Fit-over is our best-selling frame by a decisive margin - it is typically the most economical solution for welding shops looking to buy laser eyewear that will fit everyone reducing expense for individual-specific protective eyewear. In almost all situations that are not atypical (for e.g.; fitting eyewear underneath a face shield etc.), this frame is highly recommended when the choice is polycarbonate glasses.

The Model 08 - Frame FIT-over fits large and small heads and faces. Fits over most standard prescription glasses.

- Offering outstanding vision protection.

- Lateral side shields with multi-vented for comfort.

- Fits over prescription glasses up to 140mm

- Compliance: ANSI Z87.1.2020, EN166, AS/NZS1337.1, CSA Z94.3 ,AS/NZS 1067 safety standards.

Avaialble in OD7+

Model 05 - Ultra light adjustable protection Spectacle

Best in class for lightness and flexibility

- Model 05 Light weight design.

- With side shields

- Nylon frame feathers adjustable temples for a custom fit.

- Polycarbonate lens provides reliable impact resistance and Laser Light protection.

- Fully coloured lens, no coating that can be scratched off!

- Mini and very light, suitable with several application, such as glasses, helmet, ...

- Easy installation

This is our second most popular frame and is our best option for lightweight free moving and can be easily used under a face shield. When welding with a face shield, several welders forget sometimes to put the screen down, when its only for a short time, therefor its better to wear continiously a lightweight protection goggle that protects you all time.

Available in:

- green – protection range 190-450 & 800-1100nm O.D 7+ in Black frame only VLT 60%

Model 11 - Frame Fit-over

Good fitting Protection Goggles for eveyone!

The Model 11 - Frame Fit-over Spectacle fits large heads and faces. Fits over most standard smaller prescription glasses. Model 11 includes high comfort and side-protection with still a relative wide view of vision.

The Model 11 - Frame FIT-over fits large and small heads and faces. Fits over most standard prescription glasses.

- Offering outstanding vision protection.

- Lateral side shields with multi-vented for comfort.

- Fits over prescription glasses up to 130mm

- Compliance: ANSI Z87.1.2020, EN166, AS/NZS1337.1, CSA Z94.3 ,AS/NZS 1067 safety standards.

Available in:

- green – protection range 190-450 & 800-1100nm O.D 7+ in White or black frame VLT 60%

- Orange – Protection Range 190-540 O.D 3+ 800-1100nm O.D 8 in White Frame VLT 35%

MODEL 10 - O-FRAME 2.0 PRO Ventilated Ski Type Goggles with Laser Welding protective Lenses

SKI TYPE Goggles for the Active moving Welder

lasermach's O-Frame 2.0 PRO Goggles provides superb protection with unmistakable style. These affordable and durable goggles are padded and secure comfort and sophisticated ventilation properties, these goggles are a great value with many different uses. Once mounted, they do stick on your face in any position and give you continiously full protection. Ski goggles types protection goggles fit more snuggly around the eyes compared to other types of glasses, and they have a foam padding. They do not move and you can look in all directions with a very wide view!

Specifications and Features:

- Wide Lenses - extends peripheral vision for greater situational awareness

- Adjustable headband

- Padded interior for comfort

- Vented

- Frame Color- Black

LASER FACE SHIELD

Our Lasermach's adjustable laser welding face shields are designed for laser protection to the face and eyes for jobs that require more protection coverage than laser glasses or laser goggles offer. The face shield features a ratchet adjustable nape strap for a custom fit. Constructed from durable nylon. Pivoting action allows user to lift face shield while wearing.

LASER SAFETY AND PROTECTION FACE SHIELD

This large surface mask is ideal to protect not only the eyes but also the face and not only from welding or cleaning laser radiation but also from dust, sparks or particles. It is also prefect for prescription eye-glasses users when they have to wear laser safety fit-over goggles. We offer two models of laser safety and protection face shield - mask with different eyreprotection factor.

Our Welding Laser Safety Face Shields are designed for laser protection to the face and eyes for jobs that require more protection coverage than laser glasses or laser goggles offer. The face shield has a ratchet adjustable nape strap for a custom fit. Constructed from durable materials. Pivoting action allows user to lift face shield while wearing.

Laser Safety windows

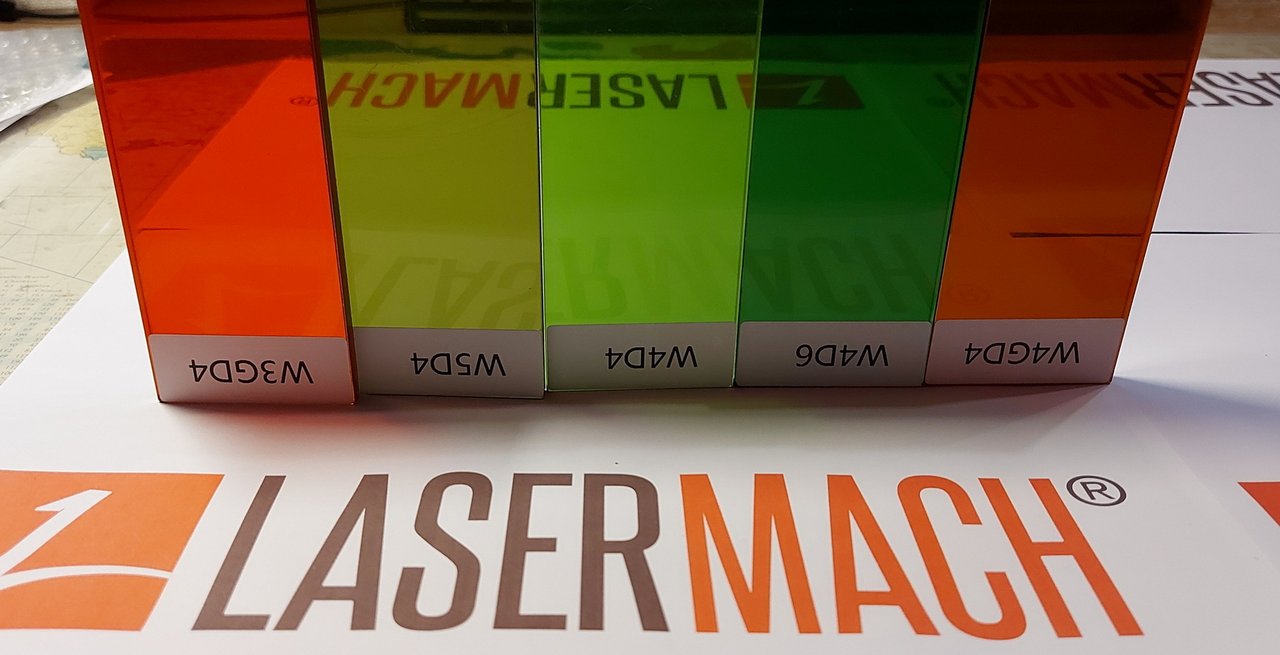

Acrylic fully coloured laser protection windows

The technological development in the field of absorbing dyes during the last years results in more and more resistant plastic/acrylic laser protection windows. In the past the plastic windows were commonly used against stray radiation. Meanwhile some plastic laser protection windows achieve a laser resistances comparable or even beter to that of mineral glass windows. A representative example therefor is the laser protection window protection+8 with 6mm thickness. Between 1030nm-1400nm it achieves with OD8+ and a 10 seconds test time an EN 207 protection level of D LB7 + IRM LB8.

An essential advantage regarding plastic/acrylic laser protection windows is the availability of much larger sheets (up to 1mx1.5m) and the lower weight. The main application range is for our windows laser welding enclosures. For such applications lasermach is offering a large variety of different acrylic laser protection windows depending on the power, wavelength and application.

Windows are not considered to be PPE and can be marked with their optical density OD only, but as a standard, most materials do have a certification acc. to EN207 and acc. DIN EN 60825-4 and indicate LB ratings.

Highlights

- Low weight, good optical properties

- Available for many laser and laser combinations

- Most window filter certified acc. EN207 with 5s and 10s

- Dimensions up to 3000mm x 2000mm for certain materials

- Some filters available in 3mm or 6mm thickness

OD to % Transmittance Conversions

Which % of the ligth can pass thru the goggle when having a specific OD number

| OD | Transmittance | Light Reduction | Which Laser Source |

|---|---|---|---|

| 1.0 | 10% | 10x less | |

| 2.0 | 1% | 100x less | |

| 3.0 | 0.1% | 1000x less | |

| .. | |||

| 6.0 | 0.0001% | 1.000.000x less | 1000 & 1500 Watt laser Welding |

| 7.0 | 0.00001% | 10.000.000x less | 1500 & 2000 Watt laser Welding |

| 8.0 | 0.000001% | 100.000.000x less | 2000 & 3000 Watt laser Welding |

| 9.0 | 0.0000001% | 1.000.000.000x less | 3000 watt and higher |

Understanding the laser safety eyewear rating

There are three parts to each LB rating

The LB number is the scale defined in the Standard EN 207:2009. This specifies eyewear protection against laser radiation using a glass or plastic material. The LB rating calculation defines the minimum markings required on the laser safety glasses to ensure protection from the specified laser, at the target distance selected.

There are three parts to each LB rating

1st: The letters in front of the LB number refer to the temporal mode of the laser beam:

D refers to CW lasers or average Power Density (exposure time > 0.25s) (our Wobble welding machine belongs to this class)

I refers to lasers with pulse lengths between 1 µs and 0.25s

R refers to lasers with pulse lengths between 1ns and 1µs

M refers to lasers with pulse lengths less than 1ns

Protective eyewear for repetitively pulsed lasers must satisfy the D rating as well as the I, R or M rating appropriate to its pulse length.

The second part defines the wavelength, or range of wavelengths, at which the rating is valid.

The final part of the CE rating is the LB rating itself.

This integer value represents the maximum power that the eyewear filters protect against.

For example:

D 532 LB3: This eyewear delivers LB3 protection for a D type beam (continuous wave) at 532nm.

DIR 1000-1300 LB5: This eyewear delivers LB5 protection for D,I and R type beams across the wavelength range 1000-1300nm.

The value of the LB numbers increase in attenuation magnitude as factors of 10. LB2 safety spectacles have ten times the attenuation of LB1 spectacles. They will withstand 10 times the power density or energy density. The minimum Optical Density of the eyewear is equal to the LB number specified. For example, a rating of LB2 means that the OD is > 2. The maximum power or energy density that the eyewear will withstand has a more complicated relationship to the Optical Density.

The minimum LB number in EN 207 is LB1. If the power or energy density of the laser is less than 0.1 times the LB limit, the low attenuation required means you might not need safety eyewear. LB10 is the largest LB rating. If the power or energy density of the laser is greater than the LB10 limit, suitable protective eyewear will probably not be commercially available. Instead, you must adapt your engineering controls to ensure that exposure to these conditions is not possible.

To determine the LB number, the actual power / energy density of the beam is used - no limit aperture is imposed on the measurement. The beam diameter has a bearing on the LB number and is different for glass or plastic eye protectors. This is due to differences in the way that they conduct heat away from the exposure area. For this reason, the LB number for Glass or Plastic protectors can be different.

For classifying alignment eyewear, standard EN 208:2009 is used. These ratings use 'RB' in place of 'LB' before the rating integer. This should not be confused with the temporal mode notation 'R'. The RB number defines the minimum markings required on laser safety goggles to ensure attenuation of the laser beam to Class 2 levels. The largest RB number defined in EN208 is RB5. Above this, safety methods must be adapted.

Defining these ratings depends on a variety of factors. For example, direct exposure hazards are generally worse than reflection hazards and require different levels of protection. Emissions from some sources may be "safe" only when viewed in that particular optical arrangement. The introduction of additional optics could actually increase the hazard to an unsafe condition. Optical fibre delivery systems also increase the potential exposure risk to more people, whilst further complicating the assessment of the base risk itself.

Understanding the CE mark is the key to understanding the safety provided by each eyewear type.

Maintenance and cleaning of your protection Goggle or protection Glasses

Meet Standards EN 207: 2009 + AC: 2011 --

Put the product into protective box delivered with the goggles when not used.

The glasses should be discarded when damage, faded or scratched.

Clean the glasses with mild detergent and cotton or with the added special tissue.

WARNING: if the goggles are damaged, cracked, have scratched oculars or which have undergone a color change, then the goggles or glasses shall not be used anymore

Packing List

1x laser safety glasses

1x red hard bag

1x cleaning cloth