What Metals can be Successfully Welded with Fiber Lasers?

Which metals can be welded with a fiber laser welding machine?

Laser Weldable Materials - Material selection

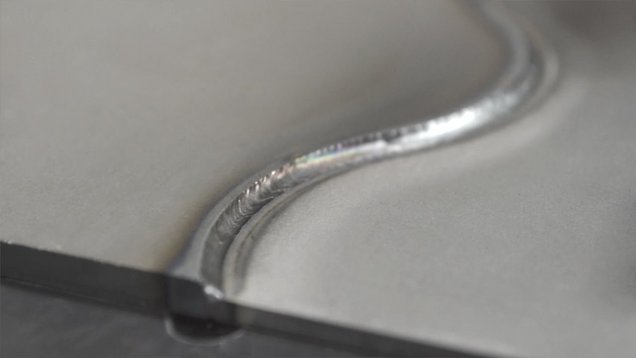

Selecting a material that satisfies both part functionality and manufacturability is fundamental to a successful laser welding process. The most common material used for micro welding is 300 series stainless steel, along with aluminum alloys and titanium. This contrasts with penetration welding, where many forms of carbon steel are welded. Next table summarizes the weldability of the most common materials used.

| Material | Comments |

| Aluminum | 1050, 3003 and 6061 to 4047 are OK. Continuous wave welding increases weldability of alloys such as 5052 and 5082. Aluminum alloys should be tested thoroughly for crack sensitivity |

| Beryllium copper | Good welds. Potential safety hazard exists from the beryllium oxide fumes |

| Carbon steel | Good welds. Carbon content should be less than 0.12% for pulsed welding, up to 0.2% for continuous wave welding |

| Copper | Good welds. High energy levels required to overcome surface reflectivity unless 532 nm wavelength welding laser used. |

| Nickel alloys | Good welds, especially with alloys such as Hastelloy-X, Inconel 600 and 718 |

| Nitinol | Good welds. Care needed to avoid brittleness |

| Phosphor bronze | Good welds |

| Stainless steel | 304 and 304L produce excellent welds 316 and 316L are OK provided Cr/Ni ratio is greater than 1.7 303 is not recommended due to cracking tendencies. Can be matched with friendlier materials such as 304. A CW laser can be used to increase weldability. 400 series require testing for crack sensitivity. |

| Titanium | Good welds |

| Tungsten | Brittle welds |

Laser Welding of Steel

Laser Welding of Mild steels

There are considerably fewer problems with plasma formation in fiber laser welding than in CO2laser welding. This is related to a large extent to the difference in the wavelengths and intensity of their laser radiation. When using mild steel, fiber laser radiation is readily absorbed by the workpiece. There is no real need for welding gases with a helium content. Argon, an inert gas, is therefore a suitable welding gas for fiber laserwelding of mild steel. For certain applications, however, reactive welding gases such as carbon dioxide, argon/10% oxygen or argon/20% carbon dioxide may be considered as alternatives.

Laser Welding of Stainless steels

The same considerations applying to mild steels, such as plasma formation and nozzle arrangement, also apply to welding gases for stainless steels. The metallurgical impact of welding gases on the weldmetal, however, differs from that on mild steels. This is due to the factthat stainless steels contain considerably larger amounts of alloying elements.

The selection of welding gases depends on the type of stainless steel – austenitic steel, ferritic steel, or austenitic-ferritic steel – and its specificalloying composition. Welding gases containing oxygen and carbondioxide should generally be avoided. Oxygen leads to oxide inclusions in the weld metal and on the surface, which may decrease corrosionresistance. Carbon dioxide oxidises the weld and may increase the risk of intercrystalline corrosion.

Laser Welding of Austenitic stainless steel

Austenitic steels are the most common types of stainless steel. They contain chromium and nickel as their main alloying elements. Small amounts of nitrogen are sometimes added to improve mechanical strength and pitting corrosion resistance. Superaustenitic steel is an example of an austenitic steel that has a higher alloy content, particularly with reference to molybdenum and nitrogen, than ordinary austenitic steels.

Helium, argon and argon/helium mixtures (argon/30% helium andargon/50% helium) are frequently used when working with austenitic steels. The higher the laser power, the higher the helium content that the welding gas must have in order to reduce plasma formation.

Welding gases containing hydrogen, such as argon/6–10% hydrogen,can be used at lower laser powers. Besides controlling plasma formation,hydrogen also reduces surface oxides and affects the viscosity of the melt.

Nitrogen is a suitable welding gas component for those austenitic and superaustenitic steels that are alloyed with nitrogen. Nitrogen as a welding gas compensates for loss of nitrogen in the weld metal, which would otherwise occur, thereby reducing the pitting corrosion resistance of the welds.

However, nitrogen should not be used as a welding gas for austenitic steels alloyed with titanium and niobium. Nitrogen forms nitrides with these elements, so that there is less free titanium and niobium availablefor prevention of chromium carbide formation and intercrystalline corrosion.

Laser Welding of Ferritic stainless steel

Chromium is the main alloying element of ferritic stainless steel. Inert welding gases, such as helium, argon, and argon/helium mixtures, are suitable for laser welding. Nitrogen used as a welding gas increases the nitrogen content in the melt. Therefore, nitrogen has the same effect as carbon when working with ferritic steels, i.e. it increases the quantityof martensite in the weld metal and therefore also the brittleness of the weld. Welding gases with a hydrogen content are unsuitable because ferritic stainless steels, similar to mild steels, are susceptible to hydrogen embrittlement.

Laser Welding of Austenitic-ferritic stainless steel

Austenitic-ferritic steels are also known as duplex or super duplex stainless steels. They are characterised by a two-phase microstructure containing austenite and ferrite. As a rule, the volume fractions of austenite and ferrite are equal. The main alloying elements are chromium, nickel and molybdenum. Duplex stainless steels are usually also alloyed with small amounts of nitrogen. Super duplex steel is a higher alloyed variation of austenitic-ferritic steels.

One of the problems in welding duplex steels is that the content ofaustenite in the weld bead is reduced considerably in comparison withthe parent metal. This impairs the mechanical and corrosion properties

of the joint. Using nitrogen, argon/nitrogen mixtures, or helium/nitrogenmixtures as welding gases can increase the austenite content in the weldbead, as nitrogen absorption into the weld metal promotes the formationof austenite.

Welding gases with hydrogen content should be avoided when working with duplex steels. These materials contain significant amounts of ferrite, which is susceptible to hydrogen embrittlement.

Laser welding of stainless steels sometimes requires additional protection against oxidation of the weld and/or backing gas for the root side. As a result of the high welding speed, the hot weld metal may leave the protection zone before cooling down to an uncritical temperature and may consequently react with the ambient air. In this case, an additional gas shroud can afford extra protection for the top bead.

Argon and nitrogen/hydrogen mixtures are used as backing gases for austenitic steels. However, nitrogen/hydrogen mixtures are not recommended for titanium-stabilised austenitic steels, as there is a risk of titanium nitride formation. Hydrogen-free backing gases such as argon are recommended for ferritic steels, in order to avoid the risk of hydrogen cracking. Nitrogen is suitable as a backing gas when working with duplex steels and super duplex steels, because it generates a higher amount of austenite in the weld metal.

Suitable welding gases and backing gases for laser welding of stainless steels are summarised in table under