Rules of conduct on the safe use of lasers

The following rules are of particular importance:

- Never point the laser beam at anyone’s eyes!

- Do not look directly into a laser beam!

- Always wear protection glasses!

- If the laser light accidentally strikes your eyes, close your eyes and immediately move your head out of the laser beam.

- Do not use any focusing optical device to look at the laser beam while working with lasers.

Danger of Laser radiation

Lasers used for welding applications radiate inthe infrared spectra, which are not visible to the humaneye. The intensive fiber laser light radiate in the visible spectrum but invisible for humans, is especially dangerous to the eye. Fibre laser radiation penetrate through to the retina which can be destroyed irrevocably by relatively little radiation.

Misdirected laser radiation can come directly from the laser and threaten the eyes as a result of a faulty parameter setting, an opened cover, a displaced mirror etc. Other hazards include skin burn or inflammation from combustible materials as a result of misdirected laserradiation. The greatest hazard, however, usually stems from reflected laser radiation: the major share of the laser radiation is reflected by coldmaterial first. To this we can add reflections of work piece edges, as a result of turbulence in the weld pool etc.

Misdirected radiation and reflections must be blocked off. That is why the law stipulates that the laser beam and the work zone must be in an enclosure. Beyond that, all those present, and the machine operators in particular, should wear protective goggles that are appropriate for the laser radiation being used. Fbre laser radiation are very dangerous to the eye and require special protective measures andapproved safety goggles.

Standard protective goggles made of glass or acrylic glass are not suitable at all,

as glass and acrylic glass allow fibre laser radiation to pass through!

Safety for your EYES

Safety Eyewear for laser Welding

Our Selection of Special Laser Welding protection Goggles and faceshields

Safety for your HEALTH

Fume Extraction equipment for Laser Welding

CE Safety Regulations

Safe Working with Handheld Welding lasers

Check more on CE regulations for Handheld laser Welding Machines

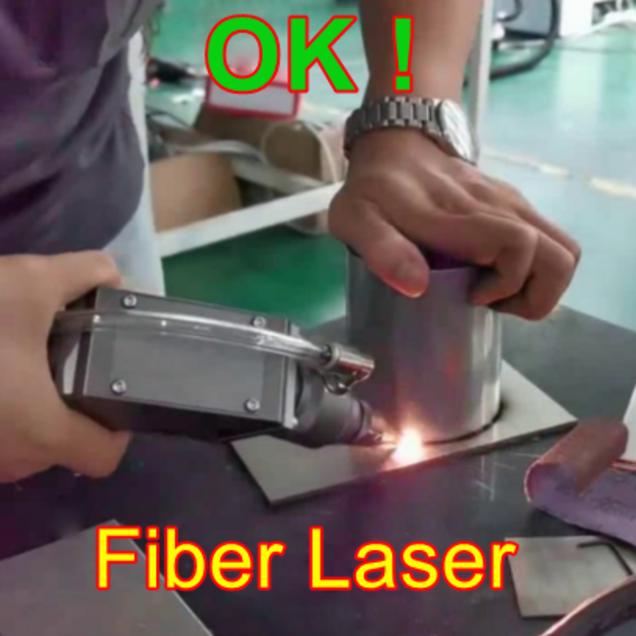

MOBILE LASER WELDER USED WITHOUT ENCLOSURE

High-power Laser Used without Enclosures

It is possible to use industrial lasers without enclosures!

However, in order to make them safe to use, personal protective equipment must be used (laser safety glasses) and access to the surrounding area needs to be controlled by interlocks or other means.

Special signage is required and other procedures must be implemented to enforce the laser-controlled area.

How to build a laser welding safe space in your workshop?

Class 4 Laser Operation Requirements for Safe Working

If you want to know how to make your safe welding zone:

Air emissions from welding: radiation, fumes, dust

First of all, we need to talk about the most dangerous emissions into the atmosphere from welding, both for professionals and for those who use the finished product.

One of the most important risk factors for you, especially for operators, comes from the radiation emitted during welding: the most dangerous are ultraviolet radiation, as it is absorbed almost entirely by the skin and eyes. The protection of each exposed area is the most effective solution. Much les dangerous is the infrared light radiation.

Welding fumes, on the other hand, are a very different problem: the effect changes according to the welded metal, going from problems with the respiratory system to damage to the skeletal system. For this reason, during welding, the work area must be well ventilated, or equipped with the right suction machinery.

Another element that requires suction are the so-called welding powders, very small particles of material with high toxicity and capable of penetrating the respiratory system. Electrode welding has the highest concentration of dust among all welding techniques, so you need to protect yourself with a mask

Danger of Welding emissions

Depending on the materials being welded, laser welding may generate fumes, altough much less than any other welding process, that are hazardous to health.

Therefore, it is important to always provide sufficient extraction and fresh air.

Safety and Health: No words needed here!

Where do you want to work?

Where does your team wants to work?

Laserlassen in Belgie - laserlassen in Nederland - Laser welding in the UK - Soudage laser en France - Soudage laser en Belgique - Soudage laser au Luxembourg - Laserschweißen in Deutschland - Laserschweißen in Österreich - Soldadura láser en españa - Saldatura laser in italia - Soldadura a laser em portugal - Laser welding in ireland - Lasersvejsning i danmark - Sudarea cu laser în Romania - Soudage laser en Suisse - Laserschweißen in der Schweiz - Laser bidezko soldadura espainian - Laser bidezko soldadura espainian - Laserové svařování v česku - Laserové zváranie na slovensku - Lasersko varjenje v sloveniji - Lasersko zavarivanje u hrvatskoj - Lasersko zavarivanje u bosni - Ласерско заваривање у Србији - Лазерно заваряване в българия - Συγκόλληση με λέιζερ στην Ελλάδα - Spawanie laserowe w Polsce - Лазерне зварювання в Україні - Лазерная сварка в украине - Лазерная зварка ў Беларусі - Laserhitsaus Suomessa - Lasersvetsning i sverige - Lasersveising i norge - Laser welding in united states - Laser welding in canada - Soudage au laser au Canada - Türkiye'de Lazer Kaynak - ריתוך לייזר בישראל