What is laser radiation?

What is laser light?

Laser Light: It travels at 299.792.458 meters per sec. Its spectrum ranges from 100 to 1400 nanometers. It is light, and its smallest unit is a packet of energy: a photon.

In most of its natural and artificial forms, light has little power. However, a groundbreaking invention in the latter half of the 1950s increased its power and concentrated it in a small area. Thus was born a modern and revolutionary concept:

Light Amplification by Stimulated Emission of Radiation, or L.A.S.E.R.

Fiber Laser Welding

Fiber laser welding, like other laser-machining methods, is a non-contact technology that has a limited, heat-affected zone (HAZ), which is why the technology is a preferred method for welding delicate products at high speeds. Laser welding is also a more repeatable and consistent process than other welding methods, and is capable of producing high-strength bonds without the need for filler material, flux, prepping, or secondary cleaning and finishing processes. Fiber Laser Welding has enabled many applications, such as energy storage with lithium ion batteries and implantable medical devices, to be manufactured in extreme scales, at much lower costs, with greater consistency, at greater speeds, and with much less waste and quality-control issues. Moreover, a laser welding manufacturing process is much more reliable than other welding technologies, as the latest laser-welding machines require little to no maintenance, and virtually no downtime.

Click HERE to visit our new PhotonWeld Website

All latest info on ourPhotonweld Series of laser welding machines here to find

The laser as a heating source

Laser welding requires that the laser raise the temperature of the material to be welded. The fiber laser light must be absorbed by the material to induce a temperature rise. In effect, the fiber laser light beam is focused onto the material similar to the way the sun can be focused by a magnifying glass. The difference is that the laser’s power density is many orders of magnitude higher.

Laser light photons, packets of light energy that make up the laser, impinge onto the material and are partly or wholly absorbed. The energy of the photon is absorbed in the metal material and causes a heat waves within the metal. Repeated absorption of photons eventually leads to metal surface breakup and melting.

Even for metals that absorb well, such as steel, the laser is initially reflected. A small percentage of the laser is absorbed, heating the metal surface. The increased surface temperature increases the absorption of the fiber laser light photons. This creates a snowball effect, in which the material is rapidly heated by the laser, leading to melting and formation of the weld.

Fiber Laser Welding

Unlimited possibilities

Laser Welding is a welding technology used to join several metal components. A laser produces a beam of high-intensity that is concentrated into one spot. This concentrated heat source enables fine, deep welding and high welding speeds.

Traditional but old laser welding technologies, such as

continuous-wave CO2 welding lasers are limited in terms of accuracy and undesired, high heat input into the weld and

the traditional pulsed Nd:YAG welding lasers are limited by the maximum welding speed, the minimal spot size that can be achieved and the electrical to optical energy conversion efficiency that is very bad.

With the latest fiber laser welding, the output power and the oscillation form of the laser beam is possible to change. Fiber Laser Welding is also very suitable for welding materials with a high melting point or with high thermal conductivity due to a very low thermal effect during welding. The energy conversion rate is very high and all this makes fiber laser highly adaptable to various applications for use in various welding assembly processes.

The fiber laser beam used for welding can be adapted as follows and characterized by different laser oscillation modes :

Pulsed laser beam welding (ideal for spot welding)

and

Continuous laser beam welding (ideal for seam welding)

Even more applications are demanding a higher precision control, lower heat input and lower electrical energy consumption.

Fiber Laser Welding is a technology that offers optimal solution for both: spot welding AND Seam Welding.

Laser welding does not operate on the same principles as other types of welding like TIG, MIG, MAG,..

Laser welding uses a beam of light, instead of electricity, to join two pieces of metal together through a melting and cooling process.

Another key difference with laser welding is the intensity and ability to focus the heat source: the laser. The much higher, focused heat than, say, the electricity of a MIG welder or TIG welder, means that the weld occurs much more quickly. What’s more, the ability to narrowly pinpoint the weld area leads to much greater precision and more accurate and attractive weld joints.

What does this mean for you?

- Higher speeds: till 10x faster than MIG welding, and till 40x faster than TIG welding.

- Minimal/no finishing: The accuracy of the laser welding process means that little to no grinding or finishing is needed.

- Visually superior: Laser welding is ideal for straight line joints in furniture and other consumer products, since there is a much smaller heat-affected zone and a much tighter weld.

- Greater strength: A smaller heat-affected zone also means less weakening of the material.

So when wouldn’t you want to use laser welding? Thicker materials and parts where the weld joint construction does not allow the fit-up to be consistently maintained generally are not good candidates for laser welding.

Laser Wobble Welding

Fiber Laser Wobble Welding

When producing welds for industries that rely on precision, a word like “wobble” might raise some red flags. In a world of tolerances on the micrometer level, wobble sounds sloppy. Where strength and consistency are paramount, wobble seems weak and inconsistent.

But sometimes it’s out-of-the-box thinking that leads to innovation. It’s these very factors that have brought laser welding to the center stage of high-tech industries – with its high welding speeds, small heat-affected zone and consistent welds.

But like all manufacturing processes, there’s room to improve. And laser welding is no different. We improved our Wobble Laser Welder during the years to become the best!

WOBBLE - Fiber laser welding

Handheld fiber laser welding machine

FAST, ECONOMICAL and SAFE hand welding with a fiber laser light beam

A Handheld fiber laser welding machine is a new type of high-power, high-end continuous welding tool which adopts a high-quality fiber laser source to produce a fiber optic light beam. After transmission processing, the light is focused on the workpiece to achieve continuous welding. It avoids the two thresholds of thermal strain and post-treatment, and is environmentally friendly and pollution-free, greatly improving the joint strength and quality of welding.

Replacing the traditional arc welding with a hand-held fiber laser welding machine will not only facilitates the welding of molds, advertising characters, kitchen utensils, doors and windows, etc. but also makes laser welding possible in outdoor operations, which indicates that this traditional welding of electric welding, argon arc welding, etc. will soon be replaced by our wobble laser welding.

Wobble-PRO+ Series: The killers of electric welding and argon arc welding

Our Laser Wobble Welding machines will have a dramatic impact in the welding world.

What is wobble laser welding?

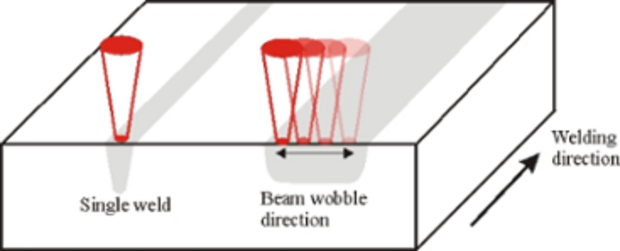

Standard laser welding heads are designed to focus a collimated laser beam to a required spot size, keeping the beam path static through the beam delivery and a static spot at the focal plane.

This standard configuration limits each setup to a specific application.

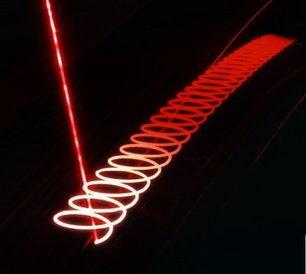

Wobble heads, on the other hand, incorporate scanning (oscilation or wobbling) mirror and lenses technology inside a standard laser weld head.

By moving the beam with internal mirrors, the focal spot is no longer static, and can be dynamically adjusted by changing the shape, amplitude, and frequency.

Fiber Laser wobble welding or Laser beam stir welding

Trepanning laser beam welding

Laser wobble welding or Laser beam stir welding is increasingly being utilized to improve weld quality, properties, and reliability for a wide range of industries, and improvements in laser beam quality and delivery capabilities are helping to spur this growth. The process has wide application in the automotive, aerospace, and fabrication industries, to name a few.

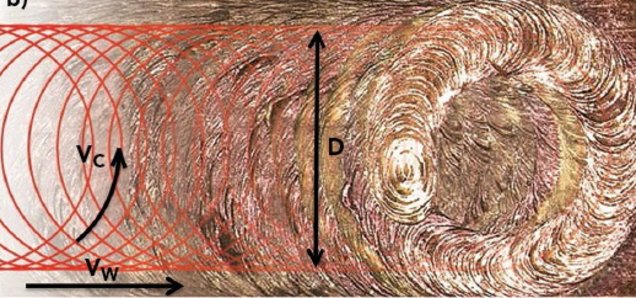

The term "laser stir welding" or "laser wobble welding" was coined to describe a process in which the laser keyhole or vapor cavity was manipulated or oscillated at a relatively high rate to cause a stirring action within a larger pool. It has also been referred to as laser beam welding with wobbling.

The phenomena is centered upon proper selection of the energy density of the laser and relative rate and motion of beam oscillation based on the thermal properties of the material being processed.

The ultimate effect when the correct parameters are chosen is the integration of energy distributed over the beam oscillation area, allowing the keyhole to cause a hydrodynamic stirring action at the rapidly moving beam. The total energy integrated over the oscillation region is responsible for maintaining the large molten pool, while the local intensity of the beam sustains the vapor cavity during oscillation and stirring within the molten pool. The rapid motion of the oscillated beam establishes a self-healing nature of the keyhole.

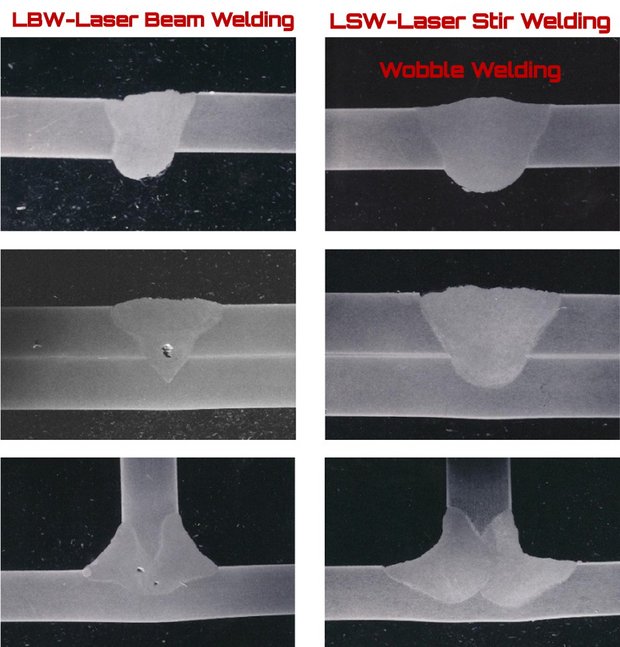

Research conducted during the development of the process had shown that laser beam welds produced on alloys using the laser stir welding process displayed less weld defects when compared to traditional laser beam welding, along with concomitant benefits of increased size of the weld to accommodate gaps and improve shear strength of lap joints, and enhanced ability to feed filler material.

applications of laser stir welding have increased significantly since its inception, based on the underlying principle that rapid oscillation of the vapor cavity within the molten pool provides a hydrodynamic stirring action that may reduce defects related to gas absorption and keyhole instability, while also providing simultaneous benefits associated with the formation of a larger weld pool.

Laser Beam Welding Vs Laser Beam wobble Welding (or Laser beam stir welding)

Laser Beam Welding (LBW) is a material-joining technique that applies laser radiation to melt the base material and create the welding joint. Laser beam welding process is related to other traditional welding methods, such as electron beam welding (EBW), tungsten plasma arc welding (PAW), or inert gas tungsten arc welding (TIG).

Laser beam welding applies a high power industrial laser to create a narrow and deep melt pool between the parts to be welded. Laser is a highly concentrated heat source that can be easily automated and installed on industrial welding cells or mounted in a handheld gun like our wobble-3, providing high welding speeds for many industrial applications.

Nevertheless, factors such as the laser beam quality or the processed materials have a great influence on the resulting geometry, microstructure, and residual stress distribution. Therefore, final results are directly dependent on the process input parameters, which means that process parameters must be carefully selected for achieving the desired quality.

Laser Stir Welding (LSW) - (LWW Laser Wobble Welding) utilizes some form of beam manipulation to oscillate the keyhole or vapor cavity within a larger molten pool. It requires a relatively high rate of manipulation, which may be represented by circular motion or some other pattern. The manipulation of the beam, and its corresponding oscillation of the vapor cavity within the molten pool, is utilized in conjunction with motion used for the welding path.

Photonic Innovation - "Enlightening" Applications

Exploring the Edges of Photonic Applications for Metal Working

Wobble Laser Welding Visually explained

Due to the small spot size of the laser, the heat input is typically 200 times lower than with arc welding processes like MIG, MAG or TIG welding.

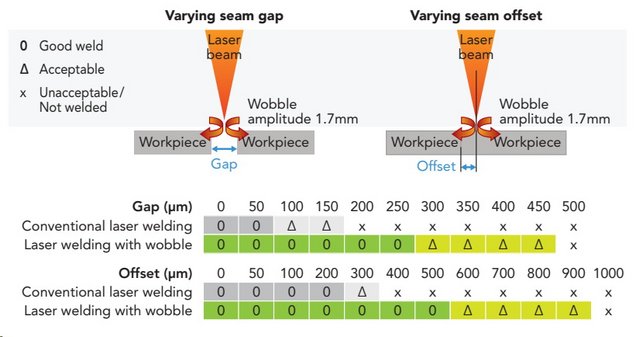

To fully reap the benefits of laser welding, a fabricator must commit with a normal laser welding machine to high-quality sheet metal processing prior to welding.

As a rule of thumb: material gaps in the weld zone should be limited to approximately maximum 0.10~0.12mm, although this can limit can be extended to gaps of 0.50~0.80mm and more with our new wobble6-PRO+ laser welding torch with adjustable welding width.

Luckily, these tolerances are easily met by modern 2D laser cutting machines and press brakes. Although parts can typically be converted from arc welding to laser welding with just minor adjustments to the design, laser welding does provide design engineers with new opportunities, such as overlap welds, corner welds and flange welds. Even complex joint geometries like curved shapes or materials with different sheet thicknesses can be laser welded easily.

Laser stir welding (wobble welding) involves the manipulation of the laser beam to provide hydrodynamic stirring and subsequent healing of the keyhole.

To achieve the wobble method, a fixed laser is optically manipulated with attachments, such as our wobble head, that allow the laser to wobble to a programmed pattern down the seam of the weld. The wobble method produces a superior weld by greatly reducing imperfections, increasing consistency, reducing material cost and providing more tolerance for process variables.

Laser Stir Welding - Laser Wobble Welding

Laser stir welding or Wobble Welding is a process in which a continuous beam laser is oscillated or wobbled at a relatively high frequency, which causes a stirring action within the molten weld pool – hence the term “stir welding or Wobble Welding.” The result is a manipulation of the weld pool/vapor cavity, which changes some key characteristics of the weld.

Benefits:

- Laser Stir Welding results in largely defect free joints, with no hot cracking, porosity or solidification cracks.

- More precise control of the weld pool for increased keyhole stability.

- Improved control of the profile and geometry of the weld – as an example, joints can be designed with more width at the root of the weld, which can be very useful for Lap/Thru-/Blind welds.

- Weld profiles can be manipulated into asymmetry, such as increasing the penetration on one side of the weld joint.

- Patterns can be programmed to compensate for large gaps in weld joints and other potentially problematic weld geometry problems.

- Higher feed rates can be achieved than with pulsed laser techniques.

- No filler materials is required.