Lassen van ongelijke metalen - Verschillende metalen: perfecte verbinding door middel van fiberlaser

Zoals bij elk lasproces, noodzaakt het maken van een goede laserlas om veel variabelen correct te respecteren.

De lasbaarheid van een materiaal is een factor. De meest voorkomende materialen die een fabriek zal verwerken - of het nu koolstofstaal, roestvrij of aluminium is - zijn al jaren met succes lasergelast, met behulp van zowel continue golf- als gepulseerde modi. Lasers hebben lassen van ongelijksoortige metalen uitgevoerd (voorbeeldfoto is koper verbonden met roestvrij staal door een fiberlaser), en gespecialiseerde lasnaadontwerpen in gegalvaniseerd materiaal hebben zelfs rekening gehouden met het uitgassen van zink. Bovendien is aangetoond dat een multikilowatt-vezellaser zelfs de meest uitdagende materialen, waaronder koper, met succes kan lassen.

Welding of dissimilar metals

In some specific markets, for example battery and medical device manufacturing, there is an increasing need to weld dissimilar materials. The trend is also found across general manufacturing, as a way to maximize part performance as individual component material can be selected for optimized operational properties rather than compromising functional properties of a lesser material to ensure weldability.

It is important to assess the metallurgy of the weld when considering two materials to weld, as many desirable dissimilar material combinations create intermetallic regions that can cause brittleness. Brittle welds are weaker than either of the two materials in the weld. Therefore, it is critical to conduct fitness for purpose testing. When assessing if a material combination is viable for a specific application, it is important to minimize heat input and laser time on the part.

Laser Lassen van plaatwerk componenten uit ongelijke metalen

Verbind RVS met verzinkt staal zonder barsten, porositeit of gaten!

De mogelijkheid om producten te maken met verschillende metalen en legeringen, verhoogt de flexibiliteit van zowel ontwerp als productie aanzienlijk. Het optimaliseren van eigenschappen zoals corrosie-, slijtage- en hittebestendigheid van het eindproduct terwijl de kosten worden beheerst, is een veel voorkomende motivatie voor het lassen van ongelijksoortige metalen.

Het verbinden van RVS en verzinkt (gegalvaniseerd) staal is daar een voorbeeld van. Vanwege hun uitstekende corrosiebestendigheid worden zowel 304 roestvrij staal als verzinkt koolstofstaal op grote schaal gebruikt in toepassingen die zo divers zijn als keukenapparatuur en luchtvaartcomponenten.

Het proces stelt een aantal speciale uitdagingen, vooral omdat de zinkcoating ernstige problemen kan opleveren met betrekking tot de lasporositeit. Tijdens het lasproces zal de energie die staal en roestvast staal smelt het zink verdampen bij ongeveer 900⁰C, wat beduidend lager is dan het smeltpunt van het roestvast staal.

Door het lage kookpunt (verdampings) van zink ontstaat er dampvorming tijdens het sleutelgatlasproces. Bij het proberen te ontsnappen aan het gesmolten metaal, kan de zinkdamp vast komen te zitten in het stollende smeltbad, wat resulteert in overmatige lasporositeit. In sommige gevallen zal de zinkdamp ontsnappen terwijl het metaal stolt, waardoor gaten of ruwheid van het lasoppervlak ontstaan.

Met het juiste verbindingsontwerp en selectie van laserprocedureparameters, worden cosmetische en mechanisch verantwoorde lassen gemakkelijk geproduceerd. Zoals hieronder getoond, vertonen de boven- en onderoppervlakken van een overlappende las van 0,6 mm dik 304 roestvrij staal en 0,5 mm dik verzinkt staal geen scheuren, porositeit of gaten.

links: Bodemnaad (achterkant) van overlaplas van 304 roestvrij staal en verzinkt staal. Getoond is het verzinkte stalen oppervlak.

rechts: Bovenrand van overlaplas van 304 roestvrij staal en verzinkt staal. Getoond is het roestvrijstalen oppervlak.

Table under provides general guidelines on dissimilar material selection:

Dissimilar Material Selection Guide

| Material 1 | Material 2 | Comments |

|---|---|---|

| Aluminium | Cold rolled steel | Can be bonded - brittle intermetallics are created at the interface. Fitness for purpose testing essential. |

| Aluminium | Copper | Can be bonded - brittle intermetallics are created at the interface. Fitness for purpose testing essential. |

| Stainless steel | Nitinol | Can be bonded - brittle intermetallics are created at the interface. Fitness for purpose testing essential. |

| Stainless steel | Titanium | Can be bonded - brittle intermetallics are created at the interface. Fitness for purpose testing essential. |

| Stainless steel | Inconel | OK with certain alloys (304 with 600/700), need to watch for cracking. When welding, offset into the steel to promote high Cr/N ratio in weld metal |

| Stainless steel | Copper | OK |

| Copper | Phosphor bronze | OK |

| Titanium | Aluminium | OK with certain aluminium alloys (1xxx & Ti-6Al-4V) |

Stainles steel laser welded to zinc coated steel

Bottom view and Top View

Welding different alloys within the same family of metal should also be considered as dissimilar welding – and approached with the same caution. The common families are stainless steel and aluminum.

Welding stainless steels within the 3XX series is generally successful, but it is worth noting that 303 and 316 are problematic materials. Because 303 is a free-machining steel containing sulfur, it is poor for welding, causing cracking and porosity. However, pairing it with 304L can produce a weldable combination – providing the mixing ratio favors the 304L. This can be further mitigated by using a CW rather than pulsed laser, as the CW laser reduces the thermal cycling of the parts.

For the 316, the final chromium/nickel ratio of the weld material must be greater than 1.7 to ensure reliable welds devoid of cracking. Again, the use of a CW laser helps in welding of 316.

Welding the 4XX series can be problematic, due to its carbon content and the other alloying elements for ferrite stabilization. However, welding is generally helped by welding to 3XX steels.

Welding different aluminum alloys can be considered dissimilar material welding, due to the large differences among these alloys. The important factor is ensuring that the percentage of the alloy elements in the weld does not promote cracking. With electronic packages, seam welding is routinely completed between 6061 and 4047 aluminum alloys, because the level of Silicon (Si) in the 4047 moves the overall alloy percentage into the safe 7-8 percent range.

Joining two different aluminum alloys that are each weldable must be undertaken with an understanding of the final alloy composition. For example, when two weldable alloys such as 3003 and 5052 are welded together, they are prone to cracking.

The best way to weld steel and aluminium together is fiber laser welding

Quick and safe laser joining of steel-aluminum mixed connections

The potential benefit of functionally integrated components made of steel and aluminium has sparked global research in methods to weld these two dissimilar staple metals for many years. The ability to leverage steel and aluminium alloys in mixed metallic components could dramatically reduce the weight of automobiles and planes without sacrificing mechanical strength, and offers consumer and medical device manufacturers unique alternatives to solve thermal and electrical challenges in compact spaces. Additional benefits include formability, corrosion resistance, and lower costs. Versatile metal alloys have already served many applications today, but welding them together perfectly and repeatedly continues to be an evasive process.

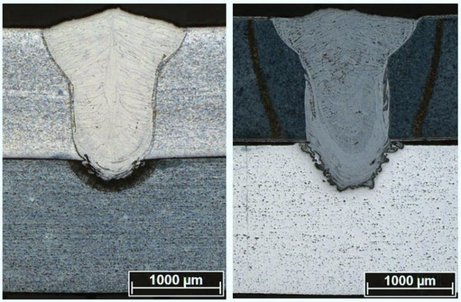

Steel to aluminium Left - Aluminium to steel Right

Robust and lightweight steel-aluminum composite components are ideal for reducing vehicle weight and can help reducing pollutant emissions. In order to optimize the joining of mixed compounds for series production in the automotive industry, the wobble laser welder has proven to be very valuable for joining two- and three-sheet metal joints with high welding speeds and good strength.

The basis for the fiber laser beam welding process is a wobbling scanner optic, newly developed with the help of Lasermach. With this, even complex three-dimensional seam geometries are possible even with large structures. Thus, the process is particularly interesting for car body construction and can replace complex robot movements.

The weld joint achieves a shear tensile strength of approximately 67 percent of the aluminum alloy. Due to the parallel arrangement of three welds, this can even be increased to about 95 percent. The process was developed for battery cases of electric cars, seat structures and car body parts. The joined mixed compounds have an advantageous crash behavior, since the joining partners remain safely connected.

Use of the laser minimizes intermetallic phases: One of the challenges in welding steel and aluminum is to avoid hard and brittle intermetallic phases in the welding seam, which cannot be completely avoided. During laser welding, a low amount of heat is introduced into the workpiece in a well targeted manner. Therefore, these phases are formed to a reduced extent and the dissimilar materials are melted as defined. Thus, it is possible to control the mixing of the joint.

To understand the benefits of the fiber laser, one can first gain insight from these pitfalls of more traditional laser welding methods:

The low miscibility of aluminum alloys and steel is a well-known phenomenon caused by very large differences in their thermophysical, electrical, and chemical properties, mainly, the melting temperature difference between aluminum at 660 °C and steel at 1538 °C. The density of aluminum is also a third of that of steel, which means it will become liquid that much faster. In addition to “floating” on the steel, liquid aluminum absorbs more laser energy than when in its solid state and results in laser-induced plasma. This often leads to porosity, hot cracks, and the formation of brittle Fe-Al intermetallic compounds. These intermetallic compounds greatly reduce the weld strength and reliability, and are often hard to predict with most welding processes.

Some success has been found with ultrasonic welding, friction welding, explosion welding, and resistance welding of aluminum alloys and steel. But these welding processes are only suitable for very specific weld joint types, and limit their use. Cold Metal Transfer (CMT), vacuum brazing, and furnace brazing has also been studied, but the mechanical strength of the weld joints is typically low. Higher mechanical strength aluminum-steel weld joints has been demonstrated with TIG, MIG, electronic beam, and laser welding.

Diffusion welding is a solid-state welding process that produces coalescence of the two metals by the application of pressure and elevated temperatures. This does work sometimes for welding together dissimilar metals like aluminum and steel. The process includes the two metals being pressed together at an elevated temperature, usually between 50-70% of the melting point and the process of diffusion occurs. It’s a tricky process to master and deliver repeatable results from, however.

Another example of a solid-state welding process is explosion welding. The process of explosion welding includes controlled detonations to fuse one metal surface to another. This process can join a wide variety of compatible and non-compatible metals together. Next to fiber laser welding, this method is an application-specific alternative.

Here's What Fiber Laser Welding Offers:

- Highly accurate control of the heat input

- Ability to automate and create higher volume throughput without major fixturing

- Low distortion for complex weld joints and shapes

- Has a small heat-affected zone (HAZ)

- Allows for high energy density welding (on advanced machines)

Moreover, like a CNC machine is to coaxial components, a programmable fiber laser machine is to welded alloy components. Unlike other welding technologies, these machines are able to be pulsed, the pulses can be shaped, and hence, the temperature of the weld joint can be precisely controlled at the molten joint. Specifically, the small focus diameter of fiber laser technology offers enhanced power density, a smaller HAZ, lower cycle time, and lower heat input which can all be documented and repeated. This can lead to a lower volume of intermetallics and even controlled intermetallic development that can be maintained over extended periods of time.

Additionally, the flexibility of fiber laser platforms also enables automated, repeatable, and reliable implementations of welding techniques that also reduce waste, porosity and sputtering common to other laser welding techniques. Moreover, even deeper control of intermetallic mixing regions has also been demonstrated with recent techniques, such as with wobble-head technology, that are able to produce stronger welds.

As these techniques are becoming more widespread, innovations in many applications, including RF, medical, and battery technology are being achieved. Also, reduced weight and complexity of automobile, aircraft, and naval ship platforms are being achieved, ultimately reducing their fuel use and environmentally damaging emissions.